Advertise Follow Us

[Video] Dealer-to-Dealer Panel: Mastering Precision Management: Implementing the Right Processes, Protocols & Practices

Paperwork and meetings may be considered necessary evils in the day-to-day workflow of a precision business, but done right, they provide invaluable insights into how to improve operational efficiency. While precision farming departments tend to have a lot of latitude and freedom, too much autonomy can produce diminishing returns and erode profit potential. As dealerships look to integrate precision training into parts, sales and service departments, having go-to guidelines and directives are essential.

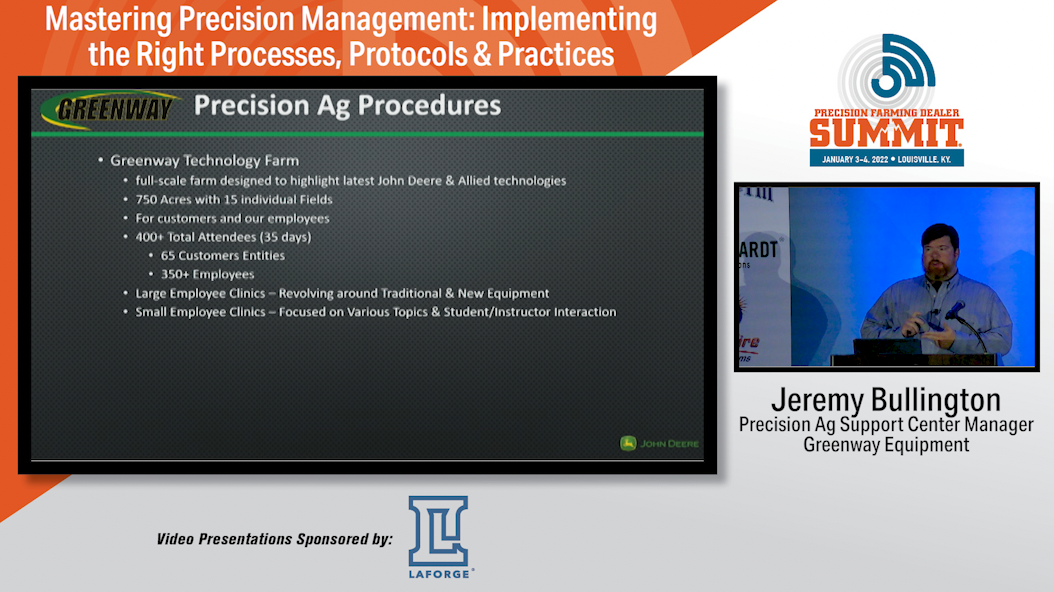

Jeremy Bullington, Precision Ag Support Center Manager, Greenway Equipment, Weiner, Ark. — Since 2017, Bullington has been responsible for project management and day-to-day coordination of the 28-location dealership’s Precision Ag Support Center, along with supervision of 4 full-time precision employees. Bullington also manages data analytics and agronomic services across nearly 300,000 acres and more than 50 distinct customer accounts, with 3 remote data analysts.

Nick Rust, Precision Ag Coordinator, H&R Agri-Power, Hopkinsville, Ky. — Rust is accustomed to the daily challenges posed by a rapidly evolving precision business, and the professional scrutiny and pressure that comes with those challenges. In July 2019, he became the 17-store Case IH dealership’s precision ag coordinator across 6 states, in charge of organization, training and oversight of the precision business, organization, training and oversight of the precision business. He’s emphasized improved communication and coordination between departments, personalized precision training and creating a standardized “precision ag specialist’s handbook” for employees to utilize as an educational resource.

Kelly Duzan, Field Sales Representative, Kuhns Equipment LLC, Gibson City, Ill. — Since the earliest days…