One of the things we’re doing at Western Sales this year is “equipment optimization,” in response to a demand for assistance on startup on seeding and spraying equipment. With the equipment increasingly complex, customer delivery and training requires more expertise than what the salesman can provide, particularly with all the digital world functions. Customers are naturally inclined to seek out our agronomists to execute and manipulate the equipment for their agronomic intentions.

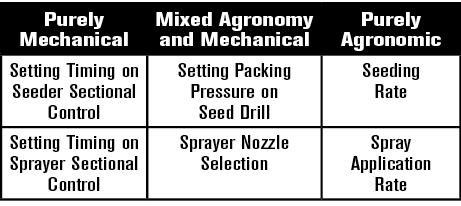

The chart at right illustrates how most of the advice customers are looking for strays from the pure mechanical/control issues into agronomic concerns.

Setting the timing on a seeder or sectional control is pretty much mechanical. Did the seed check before it crossed the prior run or not? It’s a mechanical question and it’s a matter of adjusting timing. But then you get into something like packer pressure. You can talk about what the manual says the pressure should be on the dial, but that isn’t what the customer wants to know. The customer wants to know what the right pressure is for the seeding he’s doing in his particular field. That’s more of an agronomic question, and then from there you get into the purely agronomic questions like what’s the correct rate for this soil, these moisture conditions, this seed variety, the nutrient application that’s going with it.

So as a business manager (and my past as a lawyer), when it comes to the customer asking questions and expecting certain performance from his equipment, I’m certain that putting agronomists — the production experts — in the cab with the customer is the right thing to do.

![[Technology Corner] Helping Your Customers Determine Which Technology is Right for Them](https://www.precisionfarmingdealer.com/ext/resources/2025/03/26/Helping-Your-Customers-Determine-Which-Technology-is-Right-for-Them.png?height=290&t=1743084621&width=400)