“High-speed ISOBUS is like building a new highway for super-fast cars. Unless you build the highway, nobody can actually develop the machines that go on that highway.”

— Andrew Olliver, Vice Chairman, Agricultural Industry Electronics Foundation

The Agricultural Industry Electronics Foundation (AEF) introduced new high-speed ISOBUS technology at the 2022 Commodity Classic in New Orleans in March. The next-generation ISOBUS is 4,000 times faster than the original technology, an upgrade that promises to increase precision and improve agronomy for farmers.

In this episode of the Precision Farming Dealer podcast, brought to you by Ag Express Electronics, associate editor Brian O’Connor talks with AEF vice chairman Andrew Olliver at the 2022 PlugFest about the capabilities of the new high-speed ISOBUS, its potential and the common goals of PlugFest.

The Precision Farming Dealer podcast series is brought to you by Ag Express.

Ag Express provides services and support for a wide variety of electronic and electro/mechanical devices. We can offer component level repair of an individual customers unit, or, remanufacture and rework hundreds of units for an OEM or an Electronic Manufacturer. From though hole technology to high population fine pitch surface mount, from simple units to complex industrial units.

Ag Express is 100% employee-owned and celebrating over 30 years of "Providing Possibilities!"

Full Transcript

Michaela Faulkner:

I'm Michaela Faulkner, associate editor of Precision Farming Dealer. Welcome to the latest episode of the Precision Farming Dealer podcast. New episodes of this series are available wherever you get your podcasts. Be sure to subscribe, to get an alert when upcoming episodes are released. Thanks to Ag Express Electronics for supporting this podcast series. Farmers, dealers, and those in Ag, know the importance of getting the most from their efforts. Technology has been a major game changer, when it works, when it doesn't, turn to Ag Express Electronics, who finds a way by specializing in the timely repair, support, sales and engineering of Ag technology.

Michaela Faulkner:

They provide component level repairs to save you time and money and costly replacements. They also offer wiring harnesses and other custom solutions to meet your needs. Ag express is a hundred percent employee owned and celebrating over 30 years of providing possibilities. The Agricultural Industry Electronics Foundation known as AEF, introduced the new high speed ISOBUS technology at the 2022 commodity classic in New Orleans, this March. The next generation ISOBUS is 4,000 times faster than the original technology. An upgrade that promises to increase precision and improve agronomy for farmers. In today's episode of Precision Farming Dealer podcast, associate editor, Brian O'Connor, talks with AEF vice chairman, Andrew Oliver at the 2022 Plug Fest about the capabilities of the new high speed ISOBUS, it's potential and the common goals of Plug Fest. Here's Andrew Oliver to get us started.

Andrew Oliver:

I'm employed by CNH. And I'm speaking to you today as the vice chairman for AEF. So with my AEF hat on, and I don't represent in any way the company. I'm not expressing any opinion on behalf of CNH. It's an AEM group, sort of below the Ag sector board and they're representatives from OEM companies, be they track the manufacturers or implement manufacturers, or let's say component suppliers for Ag. And because this event, one of the supporters of the commodity classic is the AEM. And I think the AEM had chosen to organize a series of meetings. And one of the meetings, they organized was the Ag technology leadership board.

Andrew Oliver:

And we kind of, in our collaboration with the AEM, because the AEM actually provides, is one of the trade industries that supports the AEF, we'd sort of realized that, there was a, I mean, and really that's also the reason why we're having the Plugfest here. Within North America, there seems to be huge gaps in the knowledge of ISOBUS systems, whether it's with the farmer, whether it's with the dealer or whether it's with also within our OEM organizations.

Brian O'Connor:

Hey, journalists are right there with you.

Andrew Oliver:

So we thought, okay, seeing as this AEM group is meeting, it will be a good opportunity to give them a tour of this. They can see what actually goes on.

Brian O'Connor:

Got it. Now you guys just announced a new ISOBUS, is that a new standard?

Andrew Oliver:

Yeah. So we had a press release for HSI or High Speed ISOBUS. And if you think about it, it's like building a new highway for super fast cars or super fast transport. And unless you build the highway, nobody can actually develop the cars or the machines that go on that highway. And so it's actually, it was a few years ago now, that the AEF started this project team, looking at okay, ISOBUS is based on canvas technology. Canvas technology is what, 250 kilobits per second. I apologize, I'm not the engineer, I can't quite remember the numbers correctly, but they-

Brian O'Connor:

General principle being higher bandwidths as you-

Andrew Oliver:

Yeah, it's finite. And basically, okay, for the majority of today's applications, the standard ISOBUS, the standard canvas is sufficient. But there are these advanced applications, if you're looking at a plant with 48 rows and you've got also advanced seeding statistics coming back to the display, you want to get that information up to the display as quick as you can, you want to have a display, which is an HD display. So it needs a lot of information coming up. We realized that, okay, to future proof this, we need greater speeds. And so this group started working and one of the first things that they did was they had to decide on what's the right technology, and then we ended up with deciding on if you're like ethernet technology, so it's a thousand gigabits per second. So we end up with a speed, which is 4,000 times greater than current ISOBUS.

Brian O'Connor:

Yeah, no, I was just thinking to myself, "Wow. If I had a 250K connection in my house, I would feel like a pauper. That's...

Andrew Oliver:

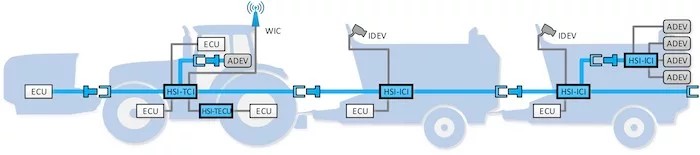

And so, it was kind of cool yesterday because this is the first time we've actually had equipment plugged together using this HSI technology. And obviously, really, this group is going to be releasing a number of AEF guidelines, which describe the different parts of this technology, whether it's the physical layer, the connectors, the cables, whether it's the application layer or the protocols, et cetera. And once these guidelines are released, then it means that manufacturers can start following these guidelines to actually develop High speed ISOBUS systems. The cool thing about this is, with this greater bandwidth, gives you so much more potential. And again, it's similar to home computing. It's similar to modem speeds and all of that. And so, the potentials are, there could be some type of diagnostic file that needs to get from the implement to the tractor?

Brian O'Connor:

Well, there was a slide where they showed one set of digital imaging and then, the kind of digital imaging is that what you're talking about?

Andrew Oliver:

Yeah. That was one thing. It is basically, it's kind of the difference between analog and digital, when you look at images and you can get so much more image quality and depth up to the display. And, then if you like the precision farming application, if you have a food grade road planter, and you're using a prescription and you're going from one prescription zone to another, the actual time that the control message takes to get from the display to the planter to say, okay, this row switches off, then that one, then that one, or this road changes right, you can end up going, okay, we've changed the rate here, and then we've gone forward how many feet before the other side of the plant has changed

Brian O'Connor:

Before that command is fully implemented.

Andrew Oliver:

And at least with HSI, you could be 48 rows, whatever, when you say let's change the rate, it happens at exactly the same time.So the precision of control is there. Another one that's good is for digital camera images. So with an HSI system, you can actually connect a whole bunch of different digital cameras to the network and all that information could get up to the display. So over analog systems, it's much more advanced.

Brian O'Connor:

And I would, further teasing that out a bit, I would assume that that kind of resolution serves as a building block, not only for like, Hey, I can see this thing that I've just cut down really well, but also things like AI.

Andrew Oliver:

Yeah.

Brian O'Connor:

That kind of thing.

Andrew Oliver:

Yeah. The potential is huge. Once you have this higher speed, the potential is huge. And then it leads on to the next question of, okay, now we have this super huge pipe, but we still have the tractor coming from one person and the implement coming from another person. And if we're working on autonomy applications, what are we going to agree on, that we can use this huge pipe, this huge data bandwidth. So that's another question we'll have to address in the future, I think.

Brian O'Connor:

It's the old hardware, software conflict.

Andrew Oliver:

Yeah,.Absolutely. But it's just, it's exciting that, this group has been working for some time, come up with a connected design. We had some of those on display yesterday and some of the AEF guidelines are already released. There's still a few more to develop, but the progress they're making is exciting. And the potential for this in the future, once we get more of these guidelines out there is really huge. And what the industry chooses to do with it, now that's the exciting piece. Yeah.

Andrew Oliver:

So again, it sort of comes back to, if you think about the subject of sustainability from the ISOBUS point of view, we're always thinking about the task controller functionality, that precision farming piece on the ISOBUS. And obviously, task controller means that you can use prescription maps. You can decide exactly what you want to put where, and get the control from the system, get a record of that coming back up to your display. But with the precision that's offered with HSI, again, you can be so much more precise in what you're applying and where you're putting it down, and then obviously in the recording of that, I think it's, yeah, they are exciting times.

Brian O'Connor:

Does that count as an additionality for carbon monitoring as well? Is that I don't know to what extent that fits effects and I know, I don't want to get you out over your skis.

Andrew Oliver:

Yeah. Well, you would be. Basically, this would allow you to control more precisely, to enter more, accurately document what you're doing. How this is analyzed afterwards, as far as carbon monitoring is up to someone else.

Brian O'Connor:

Because there was a guy on the main stage, the guy talking about data, and he said, he talked at length about additionalities and neural carbon, and I'm familiar with this just from talking to people about carbon markets. And he had mentioned that some precision agriculture was also one of the, with an eye towards, I guess, more specific nutrient applications. Those kinds of things count as additionalities, which makes you eligible for carbon market cuts.

Andrew Oliver:

Right. But again, it's about accurately documenting what you put in. And we can do that today with this HighSpeed ISOBUS. We can have greater control, more accurate control, even more accurate control of what we're doing. Which would obviously help with being able to prove, okay, this is what I applied and based on that, these are the credits I should receive, etcetera.

Brian O'Connor:

Now, the Plugfest more generally, as I understand, so two developers come in, they sit down, they try to interface basically a virtual representation of their machinery, and they have 50 minutes to do this. But they're doing it. These are conditions that farmers would sometimes not really face in the real world. They're doing it eight hours a day over and over and over again, can you explain that a little bit.

Andrew Oliver:

So basically, we are here in the Plugfest room, we've got around 16 tables set up. On each table, there is what we call an ISOBUS backbone, which represents an ISOBUS system between the tracktor and implement. The people fixed at the table for these three days are typically people that have some type type of tractor function. It could be a display supporting UT and task control of functionalities. It could be a tractor armrest supporting, we have an ISOBUS functionality called TECU or also the auxiliary control, the ability to reprogram some of the buttons on the arm rest to automatically operate something on the ISOBUS implement.

Brian O'Connor:

Kind of like assigning functions on a keyboard, in a video.

Andrew Oliver:

Yeah exactly. And so basically, the guy sitting at the table, represents something that happens on a tractor, as far as ISOBUS is concerned. And every 50 minutes, the buzzer goes and another implement or implement representative comes and sits down. And if I look at the list of what we've got here, we've got companies representing planters, companies representing round bailers or square bailers, we've got some companies which are actually EFMIS providers, we've got liquid fertilizer application systems for planters here, we've got some guys who have a guidance control system for combines, vision guidance system for combines, they're here as well. And they're all basically sitting down, one at a time at these different tables going, okay, I'll connect to the ISOBUS. And now if we look that the display, can I operate this system, does everything load correctly?

Andrew Oliver:

Can I change rates, if I'm applying something, am I recording the data correctly? And basically they've got 50 minutes to see that the systems are compatible on the ISOBUS, and then the buzzer goes, and then that implement person then moves and goes to the next table. And for these guys, it's really, really great opportunity. In three days, you can do so much testing with other ISOBUS partners and see how good your ISOBUS developments are. And sometimes you've already got systems in the market, and this is a reassurance that yes, I've done the right thing, I've released the right software. And other times you're working on something new, which is not released yet, and you're going, "Okay, I've developed this new feature, it's changed my ISOBUS code. Let's see how it works with this display or that display, and do I need to make more modifications before I release it? Or is it okay?"

Andrew Oliver:

So we have this testing, I mentioned this kind of around 16 different displays and 16 or so different implements. And there are about seven slots a day going on over three days. We also have a slot which represents the AEF conformance test. Okay. And from the AEF, we were formed in 2008, we wanted to make and we are formed by OEMs that have ISOBUS products and want to make the ISOBUS solution better for the whole industry. One of the first things we did is we said, "Okay, let's talk about ISOBUS in a simple way." We'll talk about ISOBUS in terms of functionalities. So we reach these, what we call the functionality blue squares, the idea being that, you see this blue square on the track, you see this blue square on the implement, and you know that you can use the ISOBUS system with that particular functionality.

Andrew Oliver:

Once we talked about ISOBUS in the simple way of functionalities, we then developed a conformance test, which tests for those functionalities. The idea being that every time an OEM develops a new ISOBUS product, they get it certified and it passes the conformance test. And that conformance test certifies that the product complies to the ISO standard. So 11783, plus the additional AEF guideline, which has been developed alongside the standard, to be able to have a compatible system.

Andrew Oliver:

And then finally, the last thing is, we developed a database, the AEF ISOBUS database. And that's for OEMs to use, that's for dealers to use, that's for the public, the farmers to use as well. The whole idea behind the database is that, manufacturers can list their certified ISOBUS products and dealers and farmers can access the database and look up and see what products are certified. And if they're going to buy something new, is it a new tractor? Is it a new planter? Is it a new sprayer?

Brian O'Connor:

Does It work with the equipment I have?

Andrew Oliver:

Does it work with the equipment I have?

Michaela Faulkner:

Before we get back to the conversation? I'd like to take a moment to thank Ag Express Electronics for supporting this podcast series. Farmers, dealers, and those in Ag know the importance of getting the most from their efforts. Technology has been a major game changer when it works, when it doesn't, turn to Ag Express Electronics, who finds a way by specializing in the timely repair, support, sales and engineering of Ag technology. They provide component level repairs to save you time and money and costly replacements. They also offer wiring harnesses and other custom solutions to meet your needs. Ag Express is 100% employee owned and celebrating a over 30 years of providing possibilities. Now here's Andrew Oliver, again, talking about the importance of ISOBUS compatibility testing.

Andrew Oliver:

One of the testing stations, one of the tables is actually the AEF conformance test. And it gives some of the companies that are in the room, that they might have already released an ISOBUS product on the market, but they haven't actually got it certified yet. It gives them a chance to try the AEF conformance test and see, okay, does my product pass? Does my product fail? Is there something I need to do? But ultimately, what would really make the picture so much brighter, is if every company that was developing ISOBUS products, would certify them.

Andrew Oliver:

AEF could list them in the database and so everybody could find, okay, I can see that it works with this. Yes or no, I should buy it. I shouldn't buy it. But all these certified products would be in the database, which would help everybody. But at the same time, the whole idea behind certification, is that everything is tested up to a standard, up to a certain level, and then certified products, they are compatible. They're guaranteed to be compatible on the ISOBUS. So the issues that some people see today in the field, of problems of compatibility on the ISOBUS, they'll disappear. But, everybody who's making ISOBUS products needs to be doing this conformance test.

Brian O'Connor:

Right. And also creates, I would imagine, a common market pool then, so that equipment is competing, not on the basis of whether it is, whether it meshes with technology that's existing, but more on the performance in the field.

Andrew Oliver:

Yeah. But ultimately, every company's aim is to sell more of their pieces of equipment. And the whole idea of ISOBUS is that, it's about speaking a common language so that customers are free to choose, okay, I have this color tractor, because I like it. But for the application I'm doing in the field, I don't need to buy the same color implement. I want to buy another color implement because I know it works better in my soil conditions or whatever. So by everybody following this ISOBUS standard, we're giving the customers the chance to make their own choice based on the farming conditions. Then, from the OEM point of view, the idea would be okay, how do I engineer my product? Yes. It's going to speak the common language, which the customer wants, but how do I engineer my product to give better performance so that the customer says, I want that product because I get the most benefit out it.

Brian O'Connor:

Yeah. The 50 minute thing could cause a headache for farmers, but we're not talking about 50 minutes that a guy's out there trying to get two pieces to connect, right?

Andrew Oliver:

No, no, definitely not. I mean, you know how, if you're doing a search on the internet and you are looking up some different web pages, every time you come to a new webpage, it takes a little while to load up depending on your connection speed. But then the day after you go back to that same webpage and boom, it's straight there because it's cached. It's the same here with these ISOBUS systems, is that whenever you connect a new ISOBUS implement to the ISOBUS, some base information has to be loaded up to the display and it's called the object pool.

Andrew Oliver:

And the object pool load up to the display. That does take a little bit of time, the first time it happens. But once the object pool is saved in the display, the next time, and I'm talking about the farmer here or the customer, the next time they connect, it turns that the information turns up straight away because that's been saved in the display.For these guys at the Plugfest, these engineers to do their testing correctly, whenever they connect to a new implement, So once every 50 minutes, they've always got to reset the display to-

Brian O'Connor:

To completely new.

Andrew Oliver:

To completely get rid of the object pools, everything that they previously tested to make sure the test runs correctly. So for these guys, they have this, every new connection is a new object pool upload. But obviously, like I said, from the farmer point of view, once they've done that connection once, they never have that sort of delay again, or that lost time again. The AEF released a new ISOBUS functionality called TIM, Tractor Implement Management. And that's where the implement can control certain tractor functions based on a security handshake.

Andrew Oliver:

As soon as the AEF released Tim, we saw one company get something certified for Tim and then the database. And then having that one and they were there kind of the day after the certification process was released, boom, they were there. They'd kind of been waiting for that moment. But once they had that, then slowly, we started to see, okay, they've done it now, someone else has done it. And now another tractor manufacturer has done it. And now, if you look at the database, we've got five different tractor brands with Tim functionality and we've got about six different types of implements from different manufacturers supporting Tim. But it always takes someone to be kind of the trail blazer. And I think it'll be the same in with HSI.

Brian O'Connor:

There anything else you want to add?

Andrew Oliver:

What about 20 different brands or companies represented here? Engineers get a lot of benefit from coming to Plugfest because it's a chance to speak to counterparts from other companies on this common language and obviously with a common language theres always different ways of implementing it. And one of the things that you can get from here is, someone you're testing with might say, okay, I see you've done it like this, but from what I've seen in the past, if you do it like that, you'll find that it'll be more successful. It'll be less issues, whatever. So there's this real scene of cooperation here, but it's cooperation on this common language. Everybody has their own company secrets and they're not brought here. What we're bringing here is the fact that, we all are using this common technology, this common language, and we need to be compatible using that. And we collaborate on this commonality. There's good cooperation here, but it's cooperation on the common components and-

Brian O'Connor:

The parts that need to connect

Andrew Oliver:

Secrets are left at home, or left in the office.

Michaela Faulkner:

Thanks to Andrew Oliver and Brian O'Connor for today's conversation. Let me know what you thought about this episode by emailing me at [email protected] or calling me at 2627772441. If you're looking for more podcasts about precision farming, visit precision farming dealer.com/podcasts, or check out our episode library, wherever you get your podcasts. Finally, many thanks to Ag Express Electronics for helping to make this podcast series possible from all of us here at Precision Farming Dealer. I'm Michaela Faulkner. Thanks for listening.

Intro Music: Squire Tuck - Rush to the Head

Interlude Music: Squire Tuck - Expressing One's Emotions in Public

![[Technology Corner] A Big Step Forward for Interoperability & Data Sharing](https://www.precisionfarmingdealer.com/ext/resources/2025/12/12/A-Big-Step-Forward-for-Interoperability--Data-Sharing.webp?height=290&t=1765565632&width=400)