By: Shane Thomas

There has been plenty of talk about Large Language Models (LLM) in agriculture. I have talked about it primarily through the lens of agronomy, crop input retailing and software tooling to support agribusiness professionals in sales and marketing.

The use cases are significant, though and AGvisorPRO has unlocked a high utility use case: navigating equipment manuals for equipment dealership service providers.

The average dealership has dozens of different models of tractors of their own brand tractors (eg: John Deere for a Deere dealership), but then they also have to navigate manuals for their used equipment along with the other pieces of equipment they sell, like seeders and planters or manuals from various in-cab software (eg: Trimble, Raven).

One could assume this leads to upwards of 100+ manuals to navigate for service technicians or salespeople at each dealership to get a piece of equipment set properly or fixed.

Every time a technician gets a question, it could take several minutes to access the manual, navigate the manual, interpret and synthesize the information into a usable fix for the farmer.

Not only is it time-consuming, it requires a higher cognitive load for the individual. A natural opportunity to save time and effort is with LLMs.

It’s better that basic search because not only does it retrieve the information, it can also give a basic answer that can be lightly edited before sending to the customer or interpreting oneself.

Tech Stack

The technology stack to enable generative AI is worth understanding and a helpful resource can be found from Liat Ben-Zur on Linkedin here.

A lot of what I suspect AGvisorPRO are using are generic tools available to their development team in the bottom half of the stack:

However, there is a specific area they can differentiate and create significantly more value than off-the-shelf offerings or future competitors and that’s in the top three layers of the stack, specifically in the embedded knowledge graph area.

Based on the technology stack required to enable LLM’s, my assumption is that AGvisorPRO loads all manuals into a LLM and creates proprietary nodes or embeddings to understand the manuals. Embeddings refer to a way of representing words, sentences, or other pieces of text in a relationship-based format that a computer can understand:

These representations capture the meaning and relationships between different words or texts which allow their model to navigate the manuals and deliver a summarized insight and guide to a question asked by the technician along with a reference to the specific manual and page number that can be clicked to take the individual directly to that area of the manual if they want to navigate the details further.

I was given access to trial out the software and was impressed by the results:

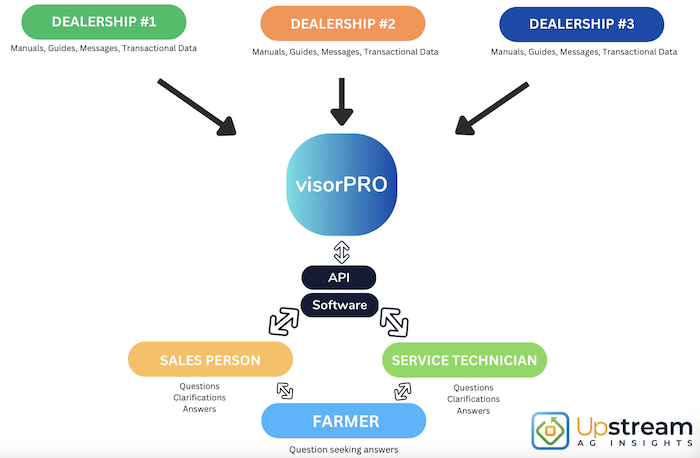

The flow of data and usage looks something like this:

To start, the visorPRO solution is a separate app and web offering, but we can see where this evolves to what I have talked about as being important when it comes to seeing success with LLMs and it illustrated within the tech stack: integration into the workflow of the service technician or salesperson software.

This includes a superior UX/UI for the user and then evolves to being integrated into the workflow. For example, API integration into the likes of service support software or a CRM database.

This announcement creates a compelling starting point for equipment dealerships, especially considering the labor challenges— being able to free up their staff’s time and deliver quicker answers to farmers who are rushing to get things done.

Business Model

While I don’t know the business model, the natural approach here is an annual fee or per API call fee paid for by the dealership. I suspect the former to start.

Agronomy Evolution

Equipment manual navigation is lower stakes than crop input recommendation. However, we can see the exact use case being applied to agronomic recommendations, which is where I have talked about LLMs the most.

Instead of building the knowledge graph off of equipment manuals, it can be built off of product labels, trial data and crop protection guides to inform information regarding crop input recommendations— such as re-entry intervals, surfactant rates, tank mix options and more.

There is a natural, albeit far-out integration for AGvisorPRO into equipment/FMS software workflow if /when they do progress towards crop protection labels.

If we think about the technology out there today, such as John Deere Sense and Act where the technology will be able to assess not only where weeds are, whether they are broadleaf or grass but get into the dynamics of the specific type of weed and whether it is resistant which will give a layered dataset that could assess historical weed pressure and suggest crop protection products based on actual field needs. This is another example of where Deere, and other equipment manufacturers, can cut into crop input manufacturer margins and contribute to influence erosion at the input retail level if the latter two groups do not look at strategically collaborating.

![[Technology Corner] Discussing AI’s Potential Impact on Service & Support](https://www.precisionfarmingdealer.com/ext/resources/2025/04/11/Discussing-AIs-Potential-Impact-on-Service--Support.png?height=290&t=1744385717&width=400)