Farmers using precision technology generate valuable data about their farming operations. Dealerships often have access to it. But how do you ensure both the dealer and the farmer are making the best use of that data? And how can you segue that efficient use of data into revenue opportunities? Jason Pennycook, precision farming specialist at Johnson Tractor, a 5-store Case IH dealer with stores in Illinois and Wisconsin, explains the steps he follows with his customers to ensure both parties get the most value out of the precision data they work with.

Start with the Basics

For Pennycook, the first step in this process is determining the best way to organize the data for each customer.

“We’ve seen a lot of customers who have been doing this for multiple years,” he says. “They have all this data, but it’s scattered, it’s mixed around, it’s not consistent. That makes it difficult to try to improve your operation when your data is not in a format that we can move around.”

Part of this means aiming for consistency. For example, operators on a farm each referring to the same field by a different name, which can cause confusion when exporting and analyzing data, Pennycook says.

Dealer Takeaways

- Protect your customers’ data with offline, local storage.

- Consider offering “a la carte” precision service options in addition to yearly plans.

- Work with local co-ops to streamline the sharing of farmers’ data.

- Optimize your customers’ equipment productivity to boost their savings.

“I have not found any father, son, grandfather or uncle who like to call a field the same name,” he says. “When you’re setting up these grower farms and fields, you need to make sure you get everyone together and they can all agree on a name.”

Pennycook shares the example of the data gathered from his own farming operation, where both he and his brother use different names and structures for the same data sets (see image above). Even simple spellings of names or the order first and last names appear can cause confusion in utilizing the gathered data.

“If you are doing this, and let’s say your customer is taking this to a co-op fertilizer guy, then they have to sort through and figure out where this data was,” he adds. “If you can get your customer started on everything being the same from the get-go, it solves a lot of problems farther down the road.”

Cooperation is another basic step Pennycook says dealers should look at, particularly by looping the customer, salesperson and precision specialist into the same conversations.

“You’re setting that customer up, and you want to make sure his grower farm field structure is right. Well, the salesman needs to be involved and needs to know what’s involved with that,” he says. “You want to get the precision specialist and the customer working together, so they get it setup right the first time so we’re not having to go back and fix it.”

OEM Solutions, Not Notepads

Pennycook stresses that, while it can still be useful in recording basic, day-to-day information, the era of using pen and paper to analyze data is over. The transition between the notepad and the OEM data collection solution, he says, is key.

“We want people collecting the data. You’re not going to improve unless you have something you can consistently look at from year-to-year to see if the decisions you’re making are correct,” he says. “A lot of guys like the cloud-based options. It’s simple, and it usually works on your tablet and your phones, meaning you can take it with you.

Johnson Tractor’s “a la carte” precision service options are an effective way the dealership can profit from working with its customers’ data without a yearly service plan.

“A lot of customers like it because it’s ‘instant gratification.’ They can have that cloud-based data collection, and they can see the pretty map right away.”

Pennycook emphasizes, however, that the “pretty map” farmers see should be functional in order to sell precision services.

Who Owns, Uses the Data?

Be clear with your customers about where the data will be stored and who can access it. Pennycook notes some customers may opt to only store their data locally and avoid cloud-based services altogether.

“We still have a lot of guys who use desktop software,” he says. “I’ve got some customers who would never put their data on a cloud server, because they’re afraid it’s going to get hacked. Their data is their data, and they don’t want anyone to have that option to see it. Desktop software is a good option for that customer. We, as a dealership, still use desktop software if we’re sorting data or trying to correct something as well.”

When helping customers utilize this data, Pennycook says Johnson Tractor does not have an in-house agronomist for farmers, meaning those decisions are usually handled by local co-ops, seed dealers and fertilizer companies. However, that can lead to additional problems in transferring information between companies.

Be Your Customers’ Source of Precision Knowledge

Jason Pennycook, precision farming specialist at Johnson Tractor, a 5-store Case IH dealer with stores in Illinois and Wisconsin, emphasizes that dealers need to continually strive to be their customers’ go-to source of precision information.

“Training is very important, because everything changes so fast,” Pennycook says. “Keep up to date. Know what you’re talking about. Make sure everyone else on your staff is up to date.

“As I like to tell everyone, ‘I do not know’ is an acceptable answer. Follow it up with, ‘I will find out the answer for you.’ You don’t have to know everything. Just let them know that you can get an answer for them.”

Training shouldn’t just be for precision farming staff either. Pennycook says everybody, including sales and service, should have the knowledge to answer basic precision questions. To Pennycook, having staff who don’t know the precision basics will prohibit them from promoting the dealership’s offered precision services to its customers.

“We found that co-ops and seed dealers aren’t quite as consistent with the growers’ farm field structure as the customer would like,” he says. “We had a situation this fall where we sold a customer a new combine, and he’d never had a yield monitor before. I go out there, and the local co-op comes out. The co-op guy says, ‘I’ve got the card with his field boundaries and field names. We can just put it in.’

“It wasn’t in the right file format, which is no problem. I’ve got my computer, so we can just load it in. We go to switch it over, and the customer is thinking he’s going to have 35-40 farms. There are 7 farms on this card in his boundaries. When they sent someone out from the co-op to make the boundaries, he went, ‘Bob’s home farm. Let’s do all the boundaries and take our soil samples.’ Well, ‘home farm’ has 6 fields. But he just called it ‘home farm’ and made it all one field.”

Pennycook recommends dealers reach out to their local co-op and other companies who will be accessing their customers’ data in order to build good relationships and train their staff on using the dealership’s data. Johnson Tractor puts in calls in both the spring and fall to local co-ops their customers use to explain the file structures the data will come in and how to set it up. Pennycook says this helps customers avoid being stuck in a field, when they’re ready to plant, with no working equipment for their data.

He stresses the importance of ensuring customer’s data is safe and secure when the dealership is trusted to work with it.

Efficiency Can Tip the Scales in Your Customers’ Favor

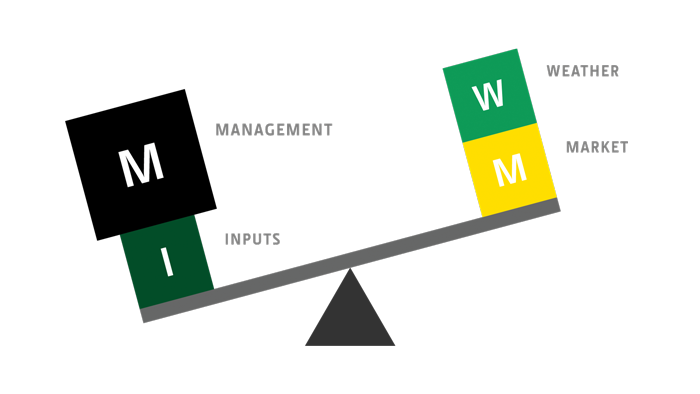

According to Layne Richins, precision ag manager for 25-store John Deere dealer Stotz Equipment, there are 4 components to a successful farming operation: inputs like equipment and fertilizer, weather, market conditions and good data management.

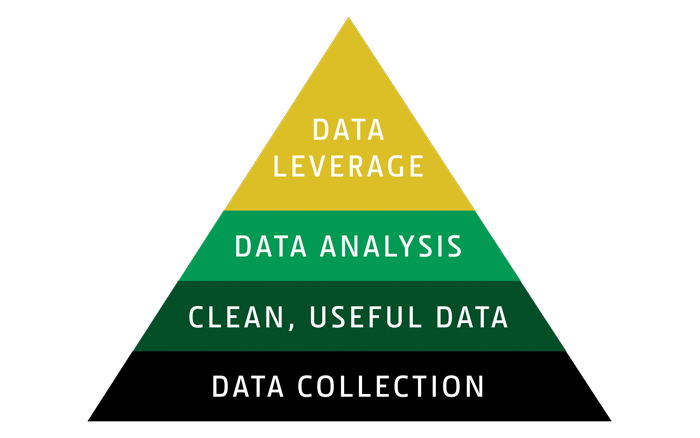

Stotz Equipment ultimately aims to move customers from the data collection phase of the precision farming pyramid all the way up to the data leverage phase, where the operator can see the best returns.

“That fourth component, management, has a major opportunity, and I think it’s a bigger opportunity than any of our inputs, our weather or our market,” he says. “When we use that management, and we place it on the side with our inputs, we then can tip the scales in our favor.

“The success of our customers has a lot more to do with the efficiency of the input — equipment, labor, processes, seed, fertilizer, chemical, water — vs. the cost of that input.”

Richins says dealers with the most control over their customers’ equipment “input” should ensure those machines are maximizing their productivity and “use the data to help them understand how to get better in their operation.”

He explains that Stotz Equipment views its customers’ usage of precision data as a pyramid, with the collection of data serving as the basis for all other applications. Where a customer falls on that pyramid determines how Stotz customizes that customer’s service plan.

“Where is our customer on this pyramid, and how do we move them up to the next level?” he says. “Once we start getting data collection, there’s going to be a package that fits them. Then once they have some data, we’ve got to clean it.

“Ultimately, we want them to be at that data leverage level, like in that example of a windrower (see “How Precision Data Can Maximize Equipment Productivity & Decrease Operator Costs” below), and you’re bringing your cost per acre from $10 to $6. That’s a significant savings.”

According to Stotz’ Layne Richins, good management can outweigh the unpredictable impact both weather and market conditions can have on a farmer’s operation.

“Like I said earlier, we have a lot of customers whose data is very important to them, and they don’t want to share it with other people,” he says. “If someone sends me data because they want me to make sure their prescriptions are going to load into their display, or they want me to clean something up, we make sure we don’t actually save all that data on our server. I have an external hard drive that all their data gets saved to. That way, it’s separate from our server so if anything ever happened, we don’t lose it.”

Saving data on local hard drives has the added benefit of being able to give it back to customers who are suddenly able to use it. For example, when a customer upgrades their tractor or planter and suddenly wants to do prescriptions, Pennycook is able to compile their locally stored data he’s been saving for years and give it to the customer’s co-op.

Making the Data Pay

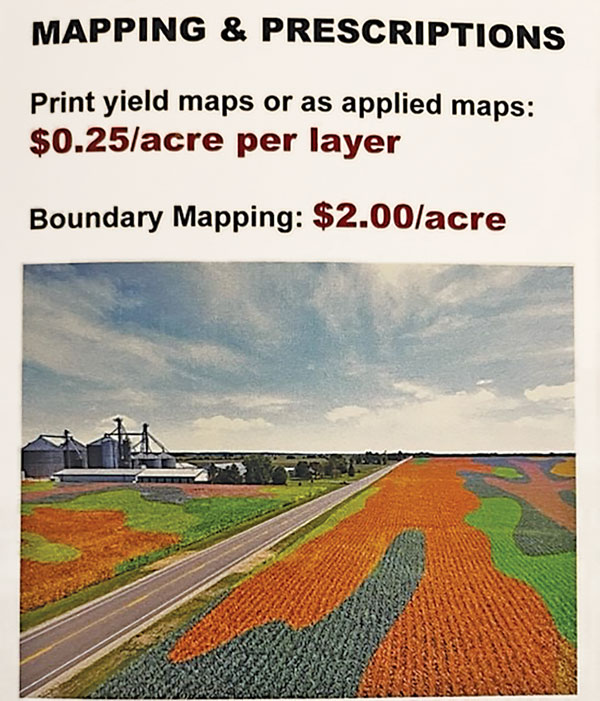

Pennycook says there are multiple ways dealers can generate revenue from their customers’ data, such as service plans on a yearly or “a la carte” basis.

“Our yearly service plans would consist of making sure your displays are up to date and making sure everything’s working,” he says. “But we do a lot of ‘a la carte’ services as well. A lot of these new things, like field boundaries, are important, especially if you’re doing waterways. Customers want section control to work. Having those boundaries mapped out on an RTK level correction for the customer is very important.”

Data cleanup is another service Johnson Tractor offers, for those situations where farmers have been storing data for years and then need access to it once they’re able to use it.

“We have growers who have been collecting data, but not actually doing anything with it for multiple years,” he says. “You may have 15 different field names, different farm names and they want to try to get it together to make it useful. We do a lot of that, where we go through and sort the data. We get everything back where it should be, so they can start with a clean slate.”

In short, Pennycook says customers go to their dealer’s precision staff for the reliable answers they can give, which is something the dealership should be billing for.

“The customer is calling you because of what you know, so make sure you’re billing out your knowledge,” he adds. “They may not want to pay for it, but if they didn’t think you knew what you were talking about, they wouldn’t be coming to you. I always try to reiterate on a yearly basis, your time has value. Make sure you are billing that time out.”

How Precision Data Can Maximize Equipment Productivity & Decrease Operator Costs

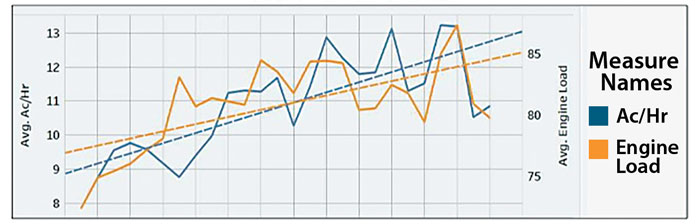

Layne Richins, precision ag manager for 25-store John Deere dealer Stotz Equipment, is a big believer in pushing equipment to its peak optimization. A good example of that is work Stotz did with a customer’s fleet of combines in Idaho, pushing the speed of the combine and tracking how it impacted acres harvested per hour.

Through optimizing the combine’s performance, Stotz Equipment was able to move one customer’s combine from harvesting 9 acres per hour to around 13 per hour.

“The blue line is acres per hour and, as you can see, when we started the season, we were running 9 acres per hour,” he says. “But as we started improving that process, improving that operation, he got up to around 12 and 13 acres per hour. That’s a pretty significant decrease in my harvest window, so I can get that crop out. Maybe I got it out before the rain event or before my protein dropped, by just utilizing the technology they have and trying to help them maximize that piece of equipment.”

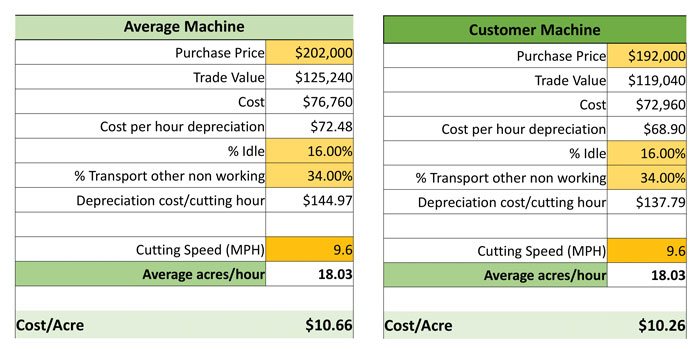

Richins outlines the 3 areas a precision specialist can focus when trying to optimize a machine’s performance, using a windrower as an example. By adjusting the machine’s purchase price, idle time and cutting speed, Richins can find the optimum settings to lower the cost per acre for his customers. Purchase price, he says, is something customers will always talk about when trying to lower their cost per acre, but it may not provide the savings they think it will. For example, saving $10,000 on the price of a windrower will only lower that customer’s cost per acre by 40 cents.

By lowering the cost of a windrower by $10,000, a customer would see a roughly 40 cent drop in their cost per acre.

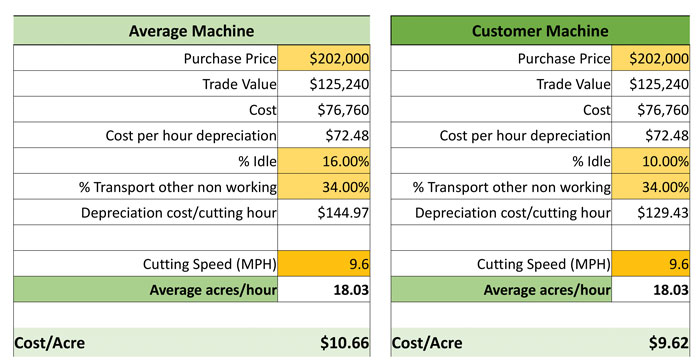

He compares this to reducing the machine’s idle time from 16% to 10%, which decreases the cost per acre by $1.00 or roughly 10%. Richins stresses that the goals they set for farmers, like this reduction in idling time, should be manageable. He says an increase in cutting speed from 9.6 mph to 10.6 mph also gives growers a $1.00 savings on their cost per acre.

Without adjusting any other parameters, a decline in a windrower’s idle time from 16% to 10% would result in a customer saving $1.00 on their cost per acre.

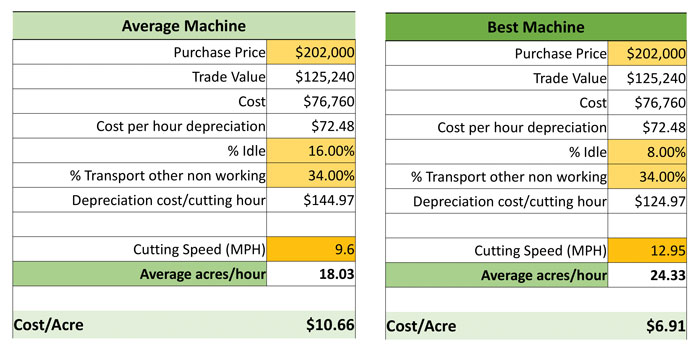

Putting the 2 metric improvements together, Richins shows how one Stotz customer was able to achieve a cost of $6.91 per acre by achieving 8% idling time and 12.95 mph cutting speed, a 35.2% reduction in cost per acre.

With manageable adjustments to idling time and cutting speed, Layne Richins shows customers can find real savings on their operations through analyzing their data.

“We have our customer here, one of our best machines,” he says. “Using those same numbers, he had an idle time around 8%. He also had a cutting speed around 12.9 mph. His cost per acre was significantly lower than the average machine. The $10,000 price difference didn’t really help much. But we have a lot more opportunity out there.”

Are We Entering Precision Farming Sales & Service 2.0?

3 Precision Managers Share Their Keys to Success

How to Prepare Your Dealership for Autonomy

Turning Data Into Efficiency to Boost Your Precision Business

Master Precision Management at Your Dealership

Shared Values & Vision are Vital to Maintaining Employee Engagement

![[Technology Corner] A Big Step Forward for Interoperability & Data Sharing](https://www.precisionfarmingdealer.com/ext/resources/2025/12/12/A-Big-Step-Forward-for-Interoperability--Data-Sharing.webp?height=290&t=1765565632&width=400)