The service department is integral to generating revenue and driving customer satisfaction. However, taking a few steps to automate the department could result in gains in efficiency and add dollars to the bottom line.

Aliese North, senior product owner with DIS, shares 5 tips on how embracing new technologies and processes allows you to run a smoother service department and also find new opportunities to achieve long-term profitability and growth. Employing even just some of these ideas can help:

- Minimize unproductive time spent in the service department by removing redundant tasks and automating processes where possible.

- Keep your service on track with work orders and efficiently reprioritize tasks by embracing the latest digital tools and technologies.

- Leverage your dealership’s analytics to gain valuable insights into your service department’s operations and identify areas that can be optimized to drive profitability.

Dealer Takeaways

- Don’t try to automate everything at once. Choose one area to focus on and implement the change before taking on the next one.

- Automating service department processes will also be a time- and money-saver for the back-office staff.

- Small changes can add up to big savings. Don’t overlook simple solutions, like automating the time clock, because 10 minutes a day for each technician adds up quickly.

1. Automate Labor Time Rounding

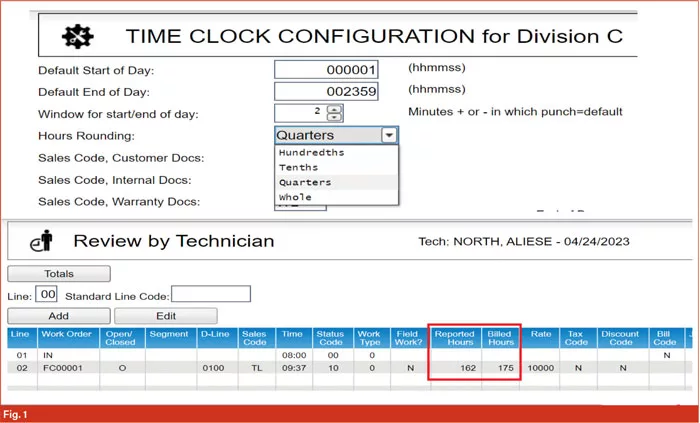

One of the easiest changes to implement, North says, is automating how labor time is rounded. This allows dealers to pick the rounding option that works best for their company, which could be rounding to the next one-hundredth, tenth or quarter of an hour.

“It’s going to depend, of course, upon the rounding option that you choose, but we tend to go with the quarter of an hour being the one that is going to provide the best bang for your buck, so to speak,” she says.

According to North, a dealer could gain at least $300 per technician per month by rounding labor time. She based this metric on a typical operation of 10 technicians and average labor rates. “If we do that math of the $300 per technician multiplied by the 10 techs, that’s $3,000 per month directly toward that bottom line,” she says.

“If we do that math of the $300 per technician multiplied by the 10 techs, well that’s $3,000 per month directly toward that bottom line…”

“What’s great about this is that on a labor-line-by-labor-line basis, you’re not really going to notice that huge change. When your customer gets the bill, they’re not going to be super shocked, but because you’re adding a little bit each time, that’s going to add up quickly.”

The example in Fig. 1 (see Above) shows the technician reported 1.62 hours for a job. By using the quarter-hour rounding technique, however, the job was billed at 1.75 hours. “Think about one labor line multiplied by all the labor lines for the technician multiplied by all the technicians at your dealership — that’s going to add up quickly,” North explains.

2. Automate Recording of Technician ‘Stories’

North says having technicians writing “stories” — or notes — on hard copies of a work order, then having the back office staff key in those notes is the “biggest waste of time in every ‘manual’ service department.”

“If they’re doing that for every work order and every technician is doing that, that’s a fairly large waste of time, especially when there are solutions out there that can help automate that process,” she says. “So even if you go simply from handwriting your story to maybe typing it into a device, you’re going to see a gain there.”

Another option here is voice-to-text. North notes the technology surrounding talk-to-text has improved significantly over the last 5 years, and the costs involved have dropped, as well.

From a measurement standpoint, North says while it will vary based on the number of segments or work orders a tech has each day, the improvement can be significant. For instance, even if it is just a 15 minute gain per technician, that amounts to about 5 hours of billable labor every month, she says. At a $100 per hour labor rate, that’s $500 per technician. If you use the average of 10 techs per operation, it’s up to $5,000 per month added to the bottom line, she explains.

“That’s just talking about how the technicians can improve their efficiency. This doesn’t even get into how the back office benefits by not having to read the chicken scratch that the technician has written and key that into the work order,” she says. “This is really a win-win situation because the technician benefits — he can more easily record his story — and the back office benefits by having that automatically come into the business system and all they’re having to do is make quick edits and off they go to the next part in the billing process.”

3. Move to Digital Scheduling

If your dealership is still using a whiteboard to schedule work in the service department, North says it’s time to update.

“I visited one dealership that, rather than using a time/date-based calendar, they had queues for each technician, and it would be a prioritized list of work,” she says. “There was a huge corkboard on the wall with hard copies of the work orders in order, and when the technician finished the top, they’d have to manually move each one up. It looked cool, but it wasn’t super efficient, especially when there are tools out there that can help automate things.”

North says to look for a tool that allows multiple users to be logged in and all seeing the same data and real-time changes as technicians make notes to a work order or someone else is adjusting the scheduler. Being able to see the status of a job — have notes been added, has a tech started a certain job, does it need to be reassigned — is another useful feature, she says.

“If the tool that you’re currently using doesn’t allow you to do those things, then you might need to take a look at some of the other options out there that do have those abilities,” North says.

North says redirecting the time spent manually updating the schedule to selling more shop labor could amount to about $1,250 per month, per scheduler.

Fig. 2 shows two different methods of planning. In the upper left corner is the queue method, where each technician has a queue of work and you’re prioritizing the work within each of their queues, North explains. This option shows a list of open work, and the user can move a job to a particular tech’s queue using drag handles to adjust the priority order as well as see the number of estimated hours planned for each technician.

The job list in the upper left corner is an example of the queue method. In this method, each technician has a queue of work, and jobs are prioritized within each tech’s queue. Open work can easily be dragged to a technician’s queue. The bottom right is a time/date-based calendar. This method shows a particular day and lists all the technicians and their jobs for that day. Source: DIS

The job list in the upper left corner is an example of the queue method. In this method, each technician has a queue of work, and jobs are prioritized within each tech’s queue. Open work can easily be dragged to a technician’s queue. The bottom right is a time/date-based calendar. This method shows a particular day and lists all the technicians and their jobs for that day. Source: DIS

In the lower right of Fig. 2 is a time/date-based calendar. On this one, “you’re going to a particular day, you’ve got all of your technicians listed. Maybe you have technicians that are more appointment-based, and so you want them to be able to schedule certain events at a particular time. You would be able to do that, as well,” North says.

4. Automate Time Clock Capabilities

What sort of time could technicians save if they weren’t walking back and forth across the shop to clock in and out? North says if technicians used a device at their workstation to punch in and out and saved 10 minutes a day, that’s 4 hours of billable time. At a $100 labor rate and 10 technicians, that’s $4,000 a month in savings.

5. Automate Technician Efficiency Data

Service managers can spend a lot of time compiling data on technician efficiency, when in reality they want to be putting the time into analyzing the data and looking for ways to improve, North says. In fact, she says that in her experience some service managers are spending so much time on the task that when dealers switch to automating it, they save $400-$800 per month.

“That’s just with the overhead time it takes to compile the reports, utilizing those reports and analyzing which technicians need improvement — and in what areas — by having them be involved in improvement actions,” she says. “That’s going to increase your technicians’ efficiency, and it’s very easy to amount that to $500 per improved technician per month. And if we multiply that by the number of technicians that you have, that’s a huge gain in efficiency.”

North advises dealers to start with one idea at a time and not to try and change everything all at once. Allow your team to adjust to the changes and slowly adopt more automation, she says.

![[Technology Corner] A Big Step Forward for Interoperability & Data Sharing](https://www.precisionfarmingdealer.com/ext/resources/2025/12/12/A-Big-Step-Forward-for-Interoperability--Data-Sharing.webp?height=290&t=1765565632&width=400)